Current Process Parameters (Spring 2020)

Processing Equipment

PVD75 Filament Evaporator

PVD75 Filament Evaporator

CVC E-beam Evaporator 2

CVC E-beam Evaporator 2

Process Procedure

In the metallization process, a layer of metal film is deposited on the wafer surface to provide electrical contacts and interconnections to devices. The metal layer can be deposited using several methods such as sputtering, evaporation and plating. In the Instructional Cleanroom, two evaporators are available to deposit metal layers. In a typical process, the chamber is pumped down to a pressure of 5 × 10-7 Torr or lower to prevent air molecules from colliding with metal atoms as they travel from the evaporation source to the substrate. The metal evaporation source is then heated to a high temperature using heat sources such as a tungsten filament or an electron-beam. This causes the metal to evaporate and be deposited on the substate. In this procedure, an example of an aluminum deposition using the PVD75 Filament Evaporator is described.

The metallization process consists of the following steps:

- LOADING WAFERS

- METAL DEPOSITION

- UNLOADING WAFERS

1. LOADING WAFERS

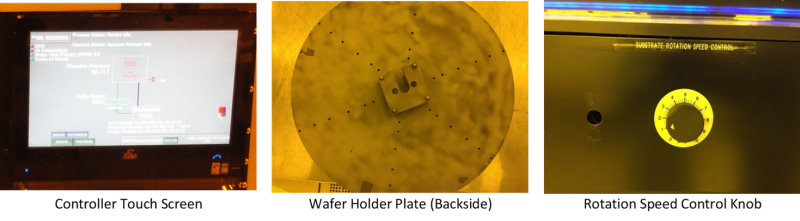

It is preferred that the wafers are cleaned by a diluted HF solution and dried to remove a native oxide layer on silicon surfaces. First, press VENT

on the overview screen of the controller, then wait for a message, VENT COMPLETE

on the screen. It takes 10 - 15 minutes. Remove the wafer holder plate from the chamber and place the wafers on the plate. Make sure that the front side of the wafers will face the source during deposition and that the wafers are securely fixed to the plate with mounting wires so that the wafers don’t slide or move during the deposition. The plate will be rotating during the deposition to achieve uniform thickness, so it is important that the wafers are securely attached to the plate. Return the plate to the chamber by placing it over the alignment pins on the rotating arm.

Press SHUTTER OPEN

on the screen to open the shutter and connect a tungsten boat on one of electrodes with a hexagon-shaped screwdriver. Then, place two or three pellets of source metal, i.e. 1-inch long rods of 99% aluminum / 1% silicon alloy, in the boat. This source can deposit up to 300 nm at once. If a thicker layer or an additional material is needed, connect another tungsten boat on other available electrodes. Press SHUTTER CLOSE

on the screen to close the shutter. Then, enable ROTOSTATE

on the screen and adjust rotation speed by using the knob under the screen. Close the chamber and press START PUMPDOWN

on the screen.

Controller and wafer plate

Controller and wafer plate

2. METAL DEPOSITION

Once the chamber pressure reaches below 5 × 10-7 Torr, the metal deposition process can be started. For the PVD75 Filament Evaporator, the pumpdown step usually takes 6 - 8 hours. In the meantime, setup a recipe for the metal deposition. Press RECIPE

on the screen, then set the values of number of steps, desired material, deposition rate (1 - 5 Å/s) and target thicknesses of each step. Press OVERVIEW

on the screen once the setup is finished.

Turn on the circuit breaker switch of the high voltage supplier and turn the power switch on. Then, press RECIPE START

on the screen to start the metal evaporation. The high power will be gradually applied to the selected filament, controlled by the film thickness controller. The steps are: RISE 1 ⇒ SOAK 1 ⇒ RISE 2 ⇒ SOAK 2 ⇒ DEPOSITION. During the deposition phase, the deposition rate and the thickness of the deposited metal layer are monitored by quartz crystal monitor. Once the target thickness is reached, the shutter is closed by the machine and the high power for the evaporation is automatically turned off.

3. UNLOADING WAFERS

After the deposition is finished, wait for at least 10 minutes to cool down the source and the wafers. Then press VENT

on the screen. If the wafer holder plate is still rotating, press ROTOSTATE

to stop it. Remove the wafer holder plate from the chamber and unload the wafers from the plate. Remove the used tungsten boats from the electrodes with the hexagon-shaped screwdriver after opening the shutter.

Press SHUTTER CLOSE

on the screen to close the shutter and replace the mylar film with a clean and transparent one. Close the chamber and press START PUMPDOWN

on the screen.

(Back to top)