Current Process Parameters (Spring 2020)

Processing Equipment

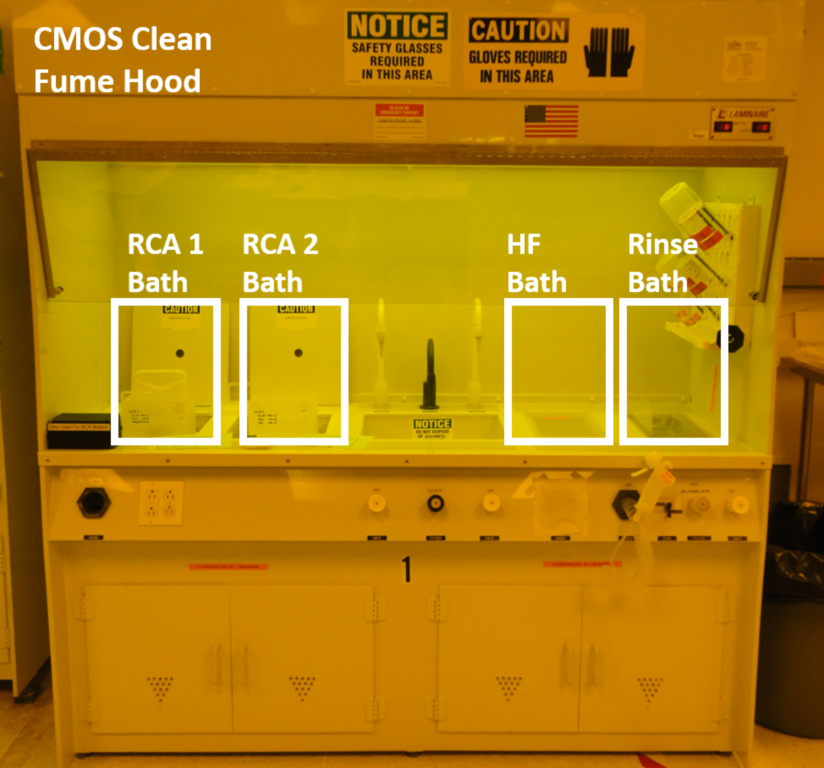

CMOS Clean Fume Hood

CMOS Clean Fume Hood

Semitool Spin Dryer

Semitool Spin Dryer

Process Procedure

The RCA clean was originally developed as a standard set of wafer cleaning steps at the Radio Corporation of America (RCA) in 1965. It is also known as Standard Clean (SC). The purpose of the RCA clean is to remove organic contaminants such as dust particles, grease and polymer residue from the wafer surface; then remove any oxide layer that may have naturally built up; and finally remove ionic or heavy metal contaminants. The RCA clean procedure should be performed immediately prior to any critical step, especially those involving high temperatures. For safety reasons, all activities in the RCA clean procedure should be performed in the CMOS Cleaning Fume hood with proper personal protection equipment (PPE).

The RCA cleaning procedure consists of the following steps:

- CHEMICAL PREPARATION

- ORGANIC CLEAN (RCA 1)

- OXIDE CLEAN (HF)

- IONIC CLEAN (RCA 2)

- DRYING

1. CHEMICAL PREPARATION

Chemicals used in the RCA clean procedure are stored in chemical storage cabinets. It is important that acids, bases, oxidizers, and solvents are always stored separately. Fresh cleaning solutions should be mixed each time an RCA clean is performed. For chemical safety, personal protection equipment (PPE) should be worn throughout the RCA clean procedure.

(RCA 1) Place a quartz bath on a hot plate after rinsing and drying it. Measure 1000 ml of D.I. water with a graduated cylinder and pour this to the prepared quartz bath for the RCA 1 Clean. Then, add 200 ml of hydrogen peroxide (H2O2) and 200 ml of ammonium hydroxide (NH4OH) to the quartz bath, respectively. Now turn on the hot plate under the bath, setting the temperature to 150 °C. The solution will be heated to 80 °C.

(RCA 2) Place another quartz bath on the other hot plate after rinsing and drying it. Measure 1000 ml of D.I. water with a graduated cylinder and pour this to the prepared quartz bath for the RCA 2 Clean. Then, add 200 ml of hydrogen peroxide (H2O2) and 200 ml of hydrochloric acid (HCl) to the quartz bath, respectively. Now turn on the hot plate under the bath, setting the temperature to 150 °C. The solution will be heated to 80 °C.

(HF) Measure 3500 ml of D.I. water with a graduated cylinder and pour this to the HF bath made of polypropylene. Then, add 70 ml of hydrofluoric acid (HF) to the HF bath.

(Rinse) Turn on the D.I. water flow valve and the nitrogen flow to the bubbler rinse bath. Adjust the water flow so it gently flows over the edge of the bath.

2. ORGANIC CLEAN (RCA 1)

Once all the solutions are prepared and have been heated to proper temperature, the cleaning process can begin. First, load wafers into a Teflon carrier. Place the carrier in a black box, labeled with RCA Clean Only,

and bring it to the CMOS Fume Hood. Attach the Teflon handle to the Teflon carrier securely. Submerge the carrier with the wafers into the RCA 1 solution for 15 minutes. Then place the wafers in the bubbler rinse bath for 5 minutes. The RCA 1 cleaning solution removes surface contaminants such as dust particles, grease, and polymer residue.

3. OXIDE CLEAN (HF)

Next, submerge the wafers in the diluted HF solution for 30 seconds. Then place the wafers in the bubbler rinse bath for 5 minutes. The Oxide cleaning solution removes thin oxide layers which have formed on the wafer surface prior to the cleaning process or during the RCA 1 clean.

4. IONIC CLEAN (RCA 2)

Next, submerge the wafers in the RCA 2 solution for 15 minutes. Then place the wafers in the bubbler rinse bath for 5 minutes. The RCA 2 cleaning solution removes metal ions.

5. DRYING

Following the RCA 2 clean, the Teflon carrier containing the wafers is placed in the black box and covered. This prevents the wafers from being re-contaminated. The spin dryer is located to the right of the CMOS Clean Fume Hood. Load the carrier into the Spin dryer carefully, keeping the H

formation inside of the chamber. Take care to ensure the carrier is properly aligned with the spin dryer grooves during loading. If there is any resistance when loading, stop, remove the carrier, and try the load procedure again. Then close the door and press the start button. The drying steps will be running while keeping the door locked. Wait until the dryer stops completely and the door is unlocked. Take out the carrier and place it in the black box.

(Back to top)